- Home

-

About VIGOR

About VIGOR

Founded in 1982, Vigor Precision Ltd specializes in design and production of High Precision Plastic Gears and Plastic Components.

MORE -

Application Fields

Application Fields

VIGOR’s products are widely applied in various fields

MORE-

Smart Home

Smart home drives the future of millions of families with intelligence

Smart home drives the future of millions of families with intelligence -

Automotive Parts

Smart travel

Smart travel -

5G Devices

Smart-drives link everything. Focus on the future of 5G

Smart-drives link everything. Focus on the future of 5G -

Medical and Health

Smart medical-care, safeguard the health

Smart medical-care, safeguard the health -

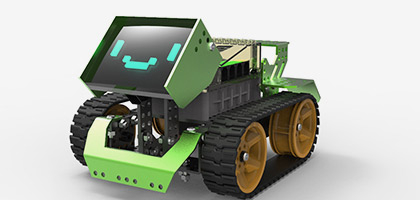

Smart Toys

One step further, making toys more than just for fun

One step further, making toys more than just for fun -

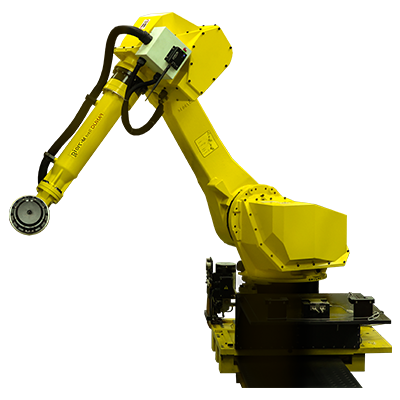

Industrial

Technology enables smart manufacturing

Technology enables smart manufacturing

-

Smart Home

-

Research / Production

Research / Production

Since establishment, Vigor has taken technology R&D and talent training as key to our development. Vigor has excellent R&D department, technical practitioners have more than 10 years of professional experience.

MORE-

R & D

With more than 100 technical staffs in R&D department, Vigor has accumulated sufficient technical reserves in the field of plastic gear production.

With more than 100 technical staffs in R&D department, Vigor has accumulated sufficient technical reserves in the field of plastic gear production. -

Production Strength

In order to ensure the quality stability of the products, we use high-precision testing instruments to ensure the quality of the products, and can monitor the whole process.

In order to ensure the quality stability of the products, we use high-precision testing instruments to ensure the quality of the products, and can monitor the whole process.

-

R & D

-

Product Series

Product Series

Vigor Precision can meet the development and manufacturing needs of different types of products.

MORE -

News

News

Vigor has been actively paying attention to industry trends since its establishment.

MORE - Contact Us

Eng /中文